Knitted wire mesh

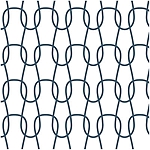

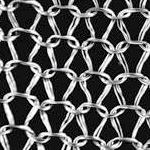

Knitted wire mesh or say knitting wire meshes also called vapor-liquid filter network, smashing net, defoaming net, foaming net, demister wire mesh, gas-liquid filter net, broken foam net, foam trap, woven wire mesh, braided wire mesh, shielded wire mesh. It is a kind of wire mesh braided in single strands, braided in multiple strands, braided with metal wires and non-metallic wires (various fibers). It can be rolled on the wire mesh to produce corrugations of various specifications as required. The roll-formed wave-shaped nets cross and stack with each other at the correct angle; the multi-layer folding expansion is to change the flow direction multiple times when the object passes through with different density, aperture and line diameter, increasing its efficiency. It can be rolled on the wire mesh to produce corrugations of various specifications as required. The roll-formed wave-shaped nets cross and stack with each other at the correct angle; the multi-layer folding expansion is to change the flow direction multiple times when the object passes through with different density, aperture and line diameter, increasing its efficiency. The opening size can be fine-tuned according to customer requirements. The open hole form is a large hole and a small hole cross arrangement (the size of the hole in the longitudinal direction is uniform and the width is different)

Stainless knitted wire mesh advantage:

- Low resistance, can be cleaned repeatedly, extremely economical;

- Ventilation system with high acid and alkali resistance and high temperature resistance.

- Safe, strong and long service life.

Knitted wire mesh usage:

- Used in the chemical industry to make wire mesh demisters, wire mesh demisters, catalysts and the elimination or capture of mist droplets and liquid mist entrained in the gas during distillation, evaporation, absorption and other processes.

- Used in oil and gas separation, oil-water separation, gas-liquid separation, shock absorption and silencer, sealing components, etc. in the manufacturing process of mechanical equipment.

- Used in dust removal, water removal, mist removal, air purification, flue gas desulfurization, water treatment equipment, oil-water separator in the field of environmental protection.

- Used in the production of components for various filtering devices; filter elements for automobiles and tractors, sealing, shock absorption (shock absorption), noise reduction and exhaust purification components in automobile parts; shielding devices for electromagnetic interference of electronic and electrical products.

Applications:

Petroleum, petrochemical, chemical, light industry, medicine, metallurgy, aerospace, marine, automotive, machinery, noise reduction and shock absorption, pressure vessels, drying towers, absorption towers, desulfurization towers, environmental protection projects for water and mist removal In the process of filtration, screening, catalyst and distillation, evaporation, absorption and other gas-liquid separation, gas-water separation.

Knitted wire mesh technical parameters:

|

No |

Item |

Description |

|

1 |

Product |

Knitted wire mesh |

|

2 |

Wire diameter |

0.07-0.55mm 0.2-0.25mm more common use |

|

3 |

Wire type |

Round or flat wire |

|

4 |

Material |

Stainless steel wire: AISI 201, 202 301, 304, 304L, 321, 316, 316L Pure Nickel, pure titanium, Monel, galvanized, modified, stainless and cutton, plastic, PP, PC, PE, PVC, PTFE |

|

5 |

Mesh braided way |

Single strands Multiple strands Braided with meatl wire and non-metallic wires |

|

6 |

Mesh surface |

Flat surface Corrugation surface |

|

7 |

Mesh opening |

2×3mm -- 4×5mm -- 12×6mm The opening size can be fine-tuned according to customer requirements. The open hole form is a large hole and a small hole cross arrangement (the size of the hole in the longitudinal direction is uniform and the width is different) |

|

8 |

Knitted wire mesh width |

40mm, 80mm, 100mm, 150mm, 200mm, 300mm, 400, 500mm, 600mm, 800mm, 1000mm, 1200mm, 1400mm Or as requirements |

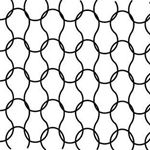

Knitted wire mesh weaving type:

SP, DP, HR/HP , single or double wire weaving.